Current and speed control gain adjustment method: VF-AS1, VF-PS1: DeviceNet function: VF-AS1, VF-PS1, DEV002Z: EtherNet/IP communication function manual. VF theory and basic operations, refer to AN887 mentioned above, and 'Speed Control of 3-Phase Induction Motor Using PIC18 Microcontrollers' (AN843). By design, PSC motors are unidirectional, which means they are designed to rotate in one direction. By adding either extra windings, and external relays. The VFC-9-200-2 Feeder Cube is a triple control for operating a vibratory bowl with a storage hopper and an inline. Unit A is a VF-9 variable frequency controller and units B & C are FC-200 fixed frequency digital controllers. Input voltage is 120VAC, 50/60 Hz. Output for Unit A is fused for 9 amps, Units B and C are fused for 5 amps each. Expansion joint /control joint- method 1. StraightFlash™ VF non flanged window detail (head).

Vf Control Methods

Current and speed control gain adjustment method: VF-AS1, VF-PS1: DeviceNet function: VF-AS1, VF-PS1, DEV002Z: EtherNet/IP communication function manual. VF theory and basic operations, refer to AN887 mentioned above, and 'Speed Control of 3-Phase Induction Motor Using PIC18 Microcontrollers' (AN843). By design, PSC motors are unidirectional, which means they are designed to rotate in one direction. By adding either extra windings, and external relays. The VFC-9-200-2 Feeder Cube is a triple control for operating a vibratory bowl with a storage hopper and an inline. Unit A is a VF-9 variable frequency controller and units B & C are FC-200 fixed frequency digital controllers. Input voltage is 120VAC, 50/60 Hz. Output for Unit A is fused for 9 amps, Units B and C are fused for 5 amps each. Expansion joint /control joint- method 1. StraightFlash™ VF non flanged window detail (head).

Vf Control Methods

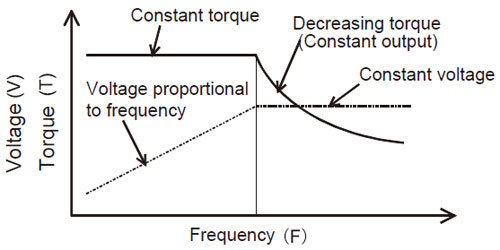

V/f Control Method Of Induction Motor

A fan application does not need torque at zero speed and really normally (unless very large) need much torque at very low speeds. A V/F drive will do fine as will a vector drive. Efficiency should be similar in both technologies. Due to volume, cost is probably similar. All ac drive manufacturers still have V/F technology for multi-motor applications. Both vector and field methodologies must have a single load, if multiple motors are used V/F must be used.

It is the best way to try it. Set a fan drive in V/F mode and measure motor current, and set in vector control mode and measure the motor current in same mechanical environment. Lower current draw in open loop vector on the same application (high inrush current application), the drives controlling the current more precisely in open loop vector mode.

Also, as a side note, most ac drives now have energy savings mode which will adjust the acceleration to keep current low while getting up speed (different AC drives manufacturers do this in different ways), as opposed to following the defined ramp, as most fans are not critical acceleration so you may consider turning on this function for additional cost savings, the larger the motor the more the savings.