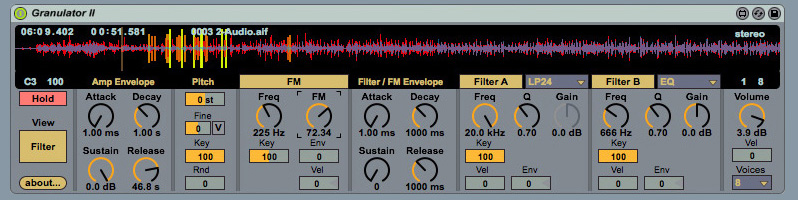

Granulator II also offers two multimode filters in series to further shape the resulting timbre. Granulator II is the latest incarnation of a series of granular based synthesizers I wrote for my own usage since the invention of MaxMSP in 1997. The instrument is a free download (CC BY-NC 3.0 license). More information: Robert Henke / Granulator II. Find here Granulator Machine, Granulator manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Granulator Machine, Granulator, Granulating Machine across India. Granulator II: TGL Series Low Speed Sound-proof Granulators (226KB).

Industrial Robot Arm for Plastic Injection Machine

Main Brochure (11.48MB)

Topstar (2.3 MB)

Topstar Robot (3 MB)

Granulator I: TGP Series Powerful Sound-proof Granulators(226KB)

Granulator II: TGL Series Low Speed Sound-proof Granulators (226KB)

Features

Swing-Arm Robots are extensively applied to horizontal/ vertical plastic injection machines ranging from 50T~250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 550mm and for telescopic is 650mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Structural Units:

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Function Features:

1.X axis can rotate 90° which is for changing molds conveniently, equipped with hydraulic shock absorber for making forward & backward stroke more stable and smooth.

2.Y axis is equipped with device to avoid pneumatic cylinder falling;

3.Z axis can be adjusted angle from 45°~90° for placing finished parts by different direction according to requirement ( to place parts at the operate side or non-operate side of injection molding machines).

Safety Protection:

External signal interlock with injection molding machine to have double safety protection for molds to ensure no locking molds if parts are not taken out via the signal confirmation of finished product removal.

Robert Henke Granulator Ii

Control System:

Palm controller, friendly operation interface, easy operation.

If you need more information for Robot and Auxuiliary equipment, welcome to reference factory webiste as:http://e.topstarltd.com/

Industrial Robot Arm for Plastic Injection Machine

Main Brochure (11.48MB)

Topstar (2.3 MB)

Topstar Robot (3 MB)

Granulator I: TGP Series Powerful Sound-proof Granulators(226KB)

Granulator II: TGL Series Low Speed Sound-proof Granulators (226KB)

Features

Swing-Arm Robots are extensively applied to horizontal/ vertical plastic injection machines ranging from 50T~250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 550mm and for telescopic is 650mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Structural Units:

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Features

Swing-Arm Robots are extensively applied to horizontal/ vertical plastic injection machines ranging from 50T~250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 550mm and for telescopic is 650mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Structural Units:

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Function Features:

1.X axis can rotate 90° which is for changing molds conveniently, equipped with hydraulic shock absorber for making forward & backward stroke more stable and smooth.

2.Y axis is equipped with device to avoid pneumatic cylinder falling;

3.Z axis can be adjusted angle from 45°~90° for placing finished parts by different direction according to requirement ( to place parts at the operate side or non-operate side of injection molding machines).

Safety Protection:

External signal interlock with injection molding machine to have double safety protection for molds to ensure no locking molds if parts are not taken out via the signal confirmation of finished product removal.

Robert Henke Granulator Ii

Control System:

Palm controller, friendly operation interface, easy operation.

If you need more information for Robot and Auxuiliary equipment, welcome to reference factory webiste as:http://e.topstarltd.com/

Industrial Robot Arm for Plastic Injection Machine

Main Brochure (11.48MB)

Topstar (2.3 MB)

Topstar Robot (3 MB)

Granulator I: TGP Series Powerful Sound-proof Granulators(226KB)

Granulator II: TGL Series Low Speed Sound-proof Granulators (226KB)

Features

Swing-Arm Robots are extensively applied to horizontal/ vertical plastic injection machines ranging from 50T~250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 550mm and for telescopic is 650mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Structural Units:

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Function Features:

1.X axis can rotate 90° which is for changing molds conveniently, equipped with hydraulic shock absorber for making forward & backward stroke more stable and smooth.

2.Y axis is equipped with device to avoid pneumatic cylinder falling;

3.Z axis can be adjusted angle from 45°~90° for placing finished parts by different direction according to requirement ( to place parts at the operate side or non-operate side of injection molding machines).

Safety Protection:

External signal interlock with injection molding machine to have double safety protection for molds to ensure no locking molds if parts are not taken out via the signal confirmation of finished product removal.

Control System:

Palm controller, friendly operation interface, easy operation.

Granulator Ii Not In Ableton

If you need more information for Robot and Auxuiliary equipment, welcome to reference factory webiste as:http://e.topstarltd.com/